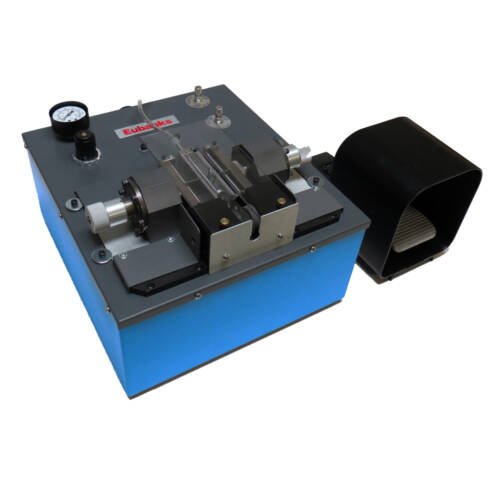

Versatile Precision Semi-Automatic Bench Stripper

The model 3751 wire and cable stripper is fast versatile and easy to use. The 3751 is ideal from simple low volume applications to relieve operators from hand stripping and up to no nick or scrape precision stripping. The 3751 can quickly strip accurately single conductor wires and many other cable types. It excels in reworking cables to the correct strip length and stripping the end of a pre-molded multi-conductor power cable. Using the special multi-conductor strip package the 3751 can strip the inner conductors of a multi-conductor cable in a single pass.

The 3751 is 100% pneumatic and very powerful. It can strip the plastic coating off pre-cut to length steel rope and also strip up to 2 AWG (33.6mm²) battery cable. There is a wide variety of tooling for most manufacturing cables that can be adapted to this small bench-stripper.

Download the Eubanks Engineering

3751 Wire & Cable Stripper specifications for more detailed information.

User Friendly

There is no learning curve required with the 3751. The machine is activated by stepping on an air operated footswitch which comfortably frees the operator’s hands. To strip a wire, simply insert the end to be stripped on the slot located in front of the 3751 or drop from the opening above. Once the wire is in position, step on the foot switch and that is all. The 3751 will automatically clamp the wire as the strip blades cut the insulation and then will fully remove it or leave it at the end semi-stripped.

Blade change is done in seconds. To change the blades, simply turn the air off, remove the top plastic guard, remove the two blade pins and change the blades. To change the strip length, simply loosen the screw on the clamp that holds the wire stop, reposition the wire stop to the desired length and retighten the clamp screw.

High-Precision

Our pneumatic strippers use unique hand machined precision die blades and blocks. These setups last years, and deliver the best quality strip available. During the strip function, the blades butt-up against one another cutting perfectly around the circumference of the conductor. During the pull to strip, the insulation is held by perfectly by both top and bottom strip blades giving a perfect linear pull when stripping. The end result is a perfect 180° square cut of the insulation without any damage to the conductor.

We design and manufacture all our own blades using our proprietary processes. These processes assure high-precision performance over a long service life. This is where Eubanks clearly excels. Customers have learned to rely on our extensive strip-blade expertise as they adapt to new insulations and tough applications.